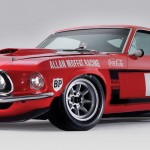

Allan Moffat’s 1969 Trans-Am Mustang

Allan Moffat’s immortal 1969 Trans Am Mustang is one of the greats of Australian motorsport. The car won 101 of 151 races it contested, and today it continues to thrill crowds as part of the incredible Bowden Car Collection.

“The Moffat Mustang is the cornerstone of our muscle car collection,” Bowden claims. “It’s just the best muscle car Australia has ever had.”

Here is the story of the car affectionately known as the “Moffstang” as told by Mark Oastler. This article original appeared in Australian Muscle Car Masters Magazine

THE GREATEST

To generations of fans, Allan Moffat’s Trans-Am Mustang is simply the greatest touring car Australia has ever seen.

Even those too young to have personally witnessed its on-track performances have grown to understand its unique status, from listening wide-eyed to countless stories told by their fathers of the excitement created every time it hit the track.

Australian enthusiasts had never seen anything like it when it erupted onto the local scene in 1969. Sure, they’d already seen earlier model notchback Mustangs driven with great skill by the likes of Pete Geoghegan, Bob Jane, Norm Beechey and others, but Moffat’s ’69 Trans-Am was like something from another planet. Here was a brand new, state-of-the-art Ford factory racer fresh from the US where it had been built to topple Chevrolet in the Trans-Am wars that year. Its shark-like nose, aggressive forward rake, ground-scraping ride height and screaming Boss 302 V8 engine left no one in any doubt about its open-cheque performance pedigree.

Looking very pretty early in its career, painted in the bright red corporate colours of big time sponsor Coca-Cola, somehow this exotic factory racer had found its way to the other side of the world to be driven by a young, little known Canadian with a single-minded determination to become Australia’s first full-time professional racing car driver. To do that, he would have to earn a lot of prize money by winning a lot of races. He certainly chose the right tool for the job.

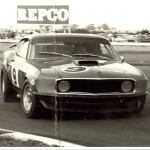

In an incredible competition career from 1969 to 1974, Moffat and his amazing Mustang amassed 101 race wins from 151 starts (or roughly two wins for every three starts!) and volumes of qualifying and lap records around the country. That stunning strike rate alone could explain this car’s fanatical following, but what made its success all the more astonishing was that Moffat was often competing against muscle monsters with far greater engine capacity. Cars like Bob Jane’s big block 7.0 litre ZL-1 Camaro, Norm Beechey’s 6.0 litre HT GTS Monaro and Pete Geoghegan’s ferocious 5.8 litre Super Falcon all towered over Moffat’s humble 5.0 litres of small block V8, during the “Improved Production” days of the Australian Touring Car Championship (ATCC) from 1969 to 1972 .

On tighter tracks with a premium on handling the Coca-Cola Mustang had no peer, yet on renowned power circuits like Sandown and Mount Panorama, Moffat and his Trans-Am could more than hold their own. This was due to the car’s superb aerodynamics, seemingly limitless reserves of braking and cornering power and its driver’s resolute determination to win.

This hard-headed approach was often criticised by his racing peers, earned the wrath of race stewards on occasions and polarised public opinion. You either loved him or you loathed him, yet the ability of Moffat and his Mustang to draw huge crowds to a race track was prized by track promoters around the country.

History records that Moffat never won the ATCC with the Mustang, after four hard years of trying. However, such a statistic is irrelevant when compared to the car’s extraordinary success rate and countless unforgettable performances that have each earned their place in history. There has never been a car like Allan Moffat’s 1969 Boss 302 Trans-Am Mustang. And there never will be. Enjoy.

TRANS-AM: A BRIEF HISTORY

The long path that led to the creation of Allan Moffat’s Mustang can be traced right back to the release of the original Mustang in 1964. America’s first “pony car” created such a buying frenzy that it wasn’t long before Ford’s major competitors in Detroit – General Motors, Chrysler Corporation and American Motors Corporation (AMC) – created their own interpretations of FoMoCo’s sexy, compact performance model fitted with potent small block V8 engines. Indeed, by 1970, the need to succeed in this hip, youth-driven market had also attracted brand divisions within these giant corporations with Lincoln-Mercury (Cougar), Chevrolet (Camaro), Pontiac (Firebird), Dodge (Challenger), Plymouth (Barracuda) and American Motors (Javelin) all competing for buyers at some stage.

Showing remarkable foresight back in 1965, America’s major road racing sanctioning body, The Sports Car Club of America (SCCA), was quick to see the potential to rapidly escalate Detroit’s pony car war by setting up a new competition category for these domestic production sedans. Commencing in 1966, the new category was divided into two classes based on engine capacity – under 2.0 litres (Group I) and over 2.0 litres (Group II) with a maximum engine capacity limit of 5.0 litres. Other key regulations included production of a minimum 1000 units of each model, 116-inch (2946mm) wheelbase, 2900 lbs (1315kgs) fuelled-up racing weight and that each race be a minimum of 2.5 hours in duration.

In another inspired move, the SCCA came up with a brilliant name for its new series – The Trans-American Sedan Championship, or “Trans-Am” for short. This series would go down in history as the catalyst for some of the greatest muscle cars and ferocious ‘knock ’em down, drag ’em out’ manufacturer-backed racing that the world has ever seen.

Commencing in early 1966, Ford boss Lee Iococca’s burning desire for his beloved Mustang to win the first Trans-Am series prompted him to contract respected sports car racer/manufacturer Carroll Shelby to prepare a small batch of ’66 notchback Mustangs designed specifically for Trans-Am competition. Shelby had already achieved road racing success for Ford with his 289ci V8-powered GT350R Mustangs in the SCCA’s B/Production sports car class, so he knew what was required to build a Trans-Am winning version.

In fact, Shelby had already supplied Pete Geoghegan with a lot of GT350R development components -including engine and suspension hardware – for his record-breaking 1965 Mustang in Australia.

As a result of Shelby’s efforts, Ford’s Mustang claimed the coveted ’66 Trans-Am Manufacturers Championship over its nearest rival Chrysler, which had fielded some potent Plymouth Barracudas.

Ford contracted Shelby to build and run another batch of notchback Trans-Am Mustangs to defend its title in 1967. SCCA added more rounds and altered the scoring system so that only manufacturers earned points, with no separate championship for drivers. This attracted private teams running GM’s all-new Camaro (as GM officially had a corporate ban on motor sport) and even prompted one of Ford’s own brand divisions, Lincoln-Mercury, to enter a factory team of Cougars prepared by Bud Moore. This move ignited a fierce season-long brawl between the two Ford camps (Moffat drove for Moore in four of these races), with Shelby’s Mustang team ultimately claiming a narrow points victory over the Cougar squad. Although Ford claimed its second straight Trans-Am title, such inter-brand fighting was considered counter-productive and the Cougar team was immediately disbanded at the end of the year.

By 1968, the Trans-Am series had, in only two seasons, enjoyed a meteoric rise in status. Expected stiff competition from “back door” GM factory teams running Chevrolet, Camaros and Pontiac Firebirds, plus some new AMC-supported Javelins, prompted Ford to raise the bar in its efforts to claim a hat-trick of Trans-Am titles. To that end, it replaced its powerful and reliable 289ci (4.7 litre) “Windsor” V8 with a new 5.0 litre small block called the “Tunnel Port” 302 – a move that would prove disastrous.

On paper at least, the new engine looked the goods with its rugged four-bolt main bearing cylinder block, forged crank/rod/piston combo and dry-deck cylinder heads. The new “Tunnel Port” heads (so named because their inlet tracts were arrow straight and so huge that the inlet valve push-rod shafts had to literally “tunnel” right through the centre of the ports rather than between them) were designed for big power at high rpm.

However, the new engine’s peaky performance characteristic and lack of low down torque made it difficult to drive on road courses. And its appalling reliability, which resulted from the need to rev the engines sky high to make them breathe properly, resulted in as many as six blow-ups on some race weekends!

As a result, Ford lost its Trans-Am title to arch rival GM, thanks to the efforts of Roger Penske, his new gun driver Mark Donohue and their potent Chevrolet Camaro team. Ford’s defeat was so humiliating, the corporation immediately laid plans for an all-out attack to win back its title in 1969, by creating what was arguably the definitive Trans-Am race car – the mighty Boss 302 Mustang.

Ford’s potent new Trans-Am weapon was odds-on favourite to win the ’69 Trans-Am, as Ford backed not only Shelby’s two-car operation but also brought Bud Moore back into the fold to run another pair of Boss 302s. Competition would come from Roger Penske’s two-car Chevrolet Camaro team, plus factory-backed entries from Pontiac (Firebird) and American Motors (Javelin).

However, despite Ford’s huge pre-season effort and a strong start to the season (four wins, two 2nds) the blue oval was again toppled by the Penske/Donohue/Camaro combo, which ended up winning eight of the 12 races. Ford’s failure was blamed on several factors, the most significant being the durability of the Firestone tyres used by Moore’s team and a huge mid-season multi-car wreck at St Jovite, Canada that caused catastrophic damage to three of the four factory team Mustangs. Despite Kar Kraft’s best efforts, the patched-up cars were never able to duplicate their formidable pre-crash form.

In 1970, the Trans-Am pony car war reached its peak. Although Ford drastically reduced its racing budget and cut back to a single two-car Mustang team for Bud Moore, the involvement of Detroit’s other big three car makers was never greater. General Motors, Chrysler and American Motors all committed serious factory backing to top-grade teams with star drivers running Chev Camaros, Pontiac Firebirds, Dodge Challengers, Plymouth Barracudas and Javelins. At season’s end, Ford finally claimed back its Trans-Am title with its prized Boss 302 Mustang.

However, Detroit’s support of the Trans-Am series collapsed at the end of the season. Ford, GM and Chrysler simultaneously pulled their factory backing over the winter, leaving Roger Penske’s AMC Javelin squad as the only works team competing in the 1971 series – which they duly won. The mass manufacturer withdrawal was blamed on pony car sales that had slowed dramatically due to rising fuel and insurance costs. Also, the Trans-Am series had become so competitive that the huge racing budgets required made it no longer cost-effective as a marketing tool. American Motors withdrew for 1972 and the era of the Trans-Am pony car factory wars was over.

However, we need to back track to 1968, when the Trans-Am series was big business and planning was underway for the 1969 Boss 302 Mustang, to understand how Allan Moffat’s immortal Mustang became a reality.

GOING ALL OUT: THE BOSS 302

The Trans-Am rules were similar to the “Series Production” rules which applied to the annual Bathurst 500 mile (800km) endurance race in Australia at the time. Put simply, the emphasis was on US car manufacturers producing a minimum number of the model they wished to race (ie 1000 units in fully street legal form available for public sale) for that model to be eligible to compete in the Trans-Am series.

By the late 1960s, Trans-Am inspired muscle cars had become not only hot showroom sellers but also potent marketing tools in a very competitive US car market. Fortunately, when it came time to create the 1969 Boss 302 Mustang, Ford had employed just the right people at just the right time. Early in 1968, self-confessed racing nut Semon “Bunkie” Knudsen, who had been driving GM’s back door racing activities, accepted Henry Ford II’s offer to become president of Ford Motor Company. Among the key people Knudsen poached from his former employer was stylist Larry Shinoda to head up Ford’s Special Design Centre.

Even though the new 1969 Mustang styling was already set in steel when he arrived, Knudsen still saw plenty of opportunities to revamp Ford’s pony car line to create the best looking and best handling road car ever to have come out of Detroit. The Boss 302 would also form the basis of Ford’s new Trans-Am racer, with credible engineering and styling links between road and race cars that would translate directly into a stampede of showroom traffic.

The inspired work of Ford’s engine, drivetrain and suspension technicians certainly achieved Knudsen’s goal in an engineering sense, but it was Shinoda’s innate feel for what was required visually that made the new Boss 302 Mustang such a knock-out in street trim.

Firstly, he made a fundamental shift from the traditional notchback body previously used by Trans-Am teams to the gorgeous lines of the new fastback shape. He also eliminated the fake air scoops from the hips of the rear quarter panels to enhance the Boss 302’s “competition-only” street cred. He fitted aerodynamic front and rear spoilers, at a time when such science was only just starting to be explored in competition. He added Lamborghini Muira-style “sports slats” to shade the rear window, liberal use of satin-black paint highlights front and back, striking full length “C” stripes down the flanks which paid homage to the Le Mans winning GT 40s, sexy Magnum 500 rims and the new low profile 60-series tyres which were only just coming into vogue.

Shinoda was so in tune with the youth market, he even came up with the name “Boss” which was a popular expression used by hip west coasters at the time to describe something that was really cool or fashionable. If there was ever a car for its time, the Boss 302 Mustang was it. And its public release in April 1969 was perfectly timed to coincide with the commencement of the 1969 Trans-Am season.

Ford was clearly hell bent on revenge. As mentioned earlier in this story, for 1969 it committed enormous financial and technical resources to provide full factory backing for not one but two race teams guaranteed to push the competition – and each other – to the limit. One team was headed by Carroll Shelby with cars for Peter Revson and Horst Kweck. The other was run by Bud Moore, who had given Shelby’s Mustang squad such a scare with his Mercury Cougar team in the ’67 Trans-Am series. His potent driver pairing was Parnelli Jones and George Follmer in two more Boss 302s.

HOW THEY BUILT MOFFAT’S TRANS-AM

At the commencement of the Boss 302 race program, Ford’s in-house race car fabrication and engineering facility “Kar Kraft” (KK) located in Brighton, Michigan built two prototype Trans-Am Mustangs specifically for evaluation by the Shelby Racing Company and Bud Moore Engineering race teams. KK had only recently played a central role in the design and development work on Ford’s big budget GT 40 sports car program, which had resulted in a much celebrated Le Mans 24-Hour race victory in 1967. Therefore, it made perfect sense to exploit such formidable in-house expertise in trying to win back the Trans-Am title.

In mid-1968, shortly after commencement of 1969 Mustang production, an internal factory order was placed for two ’69 428 Cobra Jet fastbacks, minus paint, seam sealer or sound deadener. These two cars were delivered to Kar Kraft in September ’68, then completely stripped and rebuilt from the ground up to full Trans-Am race specifications, under the supervision of KK chief designer/engineer Lee Dykstra.

Ford engineers, working closely with the Shelby and Moore race teams, then used these prototypes to conduct intensive race track engine evaluation (see engine specs) and chassis development work over several months.

When the definitive specification for the 1969 Trans-Am race cars was finalised, another internal order was placed at Ford’s Dearborn plant in December ’68 for seven more ’69 Mustang fastbacks, to be assembled minus paint, seam sealer and sound deadener, which were destined for Trans-Am duty. However, unlike the two KK-built prototypes which started out as R-code big block Cobra Jets, the seven new cars were no frills M-code (carrying sequential VIN numbers from 9F02M148623 to 9F02M148629) 351 V8s with four speed transmissions. Allan Moffat’s Trans-Am started out as one of the cars in this special batch, carrying VIN No. 9F02M148624.

Of these seven cars, one was sent to Kar Kraft, three others were shipped to Shelby Racing Company and the remaining three to Bud Moore Engineering – Moffat’s car was one of the three Bud Moore cars. The sole fastback sent to Kar Kraft was a unique hand-built racer finished in a gorgeous black with gold stripe paint scheme, for tuning legend Smokey Yunick to run in NASCAR’s ‘Baby Grand’ stock car series. The other six cars were built to Trans-Am specifications by the two race teams, based on Kar Kraft’s chassis design blueprints. The engine, drivetrain and suspension components resulting from the intense 1968 track development program were also supplied to the two teams for individual assembly.

BODY/CHASSIS UNIT

By 1969, the stakes were so high in Trans-Am racing that only those manufacturers prepared to adopt a “win at all costs” approach could expect any chance of success. Ford Motor Company, under the direction of its new boss Knudsen, embraced such a corporate philosophy with unbridled enthusiasm. This can be seen in the extent of specialised design and fabrication that went into each of the six Boss 302 race shells, which amounted to a very liberal interpretation of the Trans-Am regulations. This of course was made possible by the ambiguous wording of the SCCA rule book, which allowed Trans-Am race engineers considerable creative freedom.

The first step in Kar Kraft’s chassis preparation was minimising weight. Even though the SCCA rule book for the ’69 Trans-Am series specified a minimum weight of

2900 lbs (1315 kgs) for Group II 5.0 litre cars, the aim was to build the cars as light as possible and then bring them up to meet the minimum weight limit. This was done by securing lead or steel ballast down low at various key points in the chassis, to move the car’s standard 55.9% front v 44.1% rear weight distribution nearer to the ideal 50/50 split.

This process of moving weight rearward was further enhanced by relocating the battery from the engine bay to the boot and discreetly lowering the engine by around 50mm and moving it back as far as the firewall would allow. Mounting these heavy items as low as possible also had the effect of lowering the car’s centre of gravity (CoG) for greatly improved handling and cornering capabilities. The same thinking applied to construction of the fuel tank. This was made out of two flanged halves (ie upper and lower shells). However, a Boss 302 racer featured a much deeper bottom section than standard to drop the fuel load as close as possible to the road. This idea was duplicated in the Bathurst-style “drop tanks” seen on Torana L34 and A9X racers in the mid 1970s.

LEAN AND LOW: GO THE MOFFSTANG!

The Mustang bodyshells had already begun a weight loss program on the production line, as they were built without any weather sealing or sound deadening compounds. Kar Kraft then removed any brackets not required for competition and either drilled a zillion holes in any component that had to remain, or re-made it in aluminium. Not a single nut or bolt was overlooked in this weight loss process, right down to the internal window winding mechanisms which even had shorter crank handles to save weight.

Although acid dipping was strictly outlawed under SCCA rules on safety grounds, the practice was in fact widespread in Trans-Am to trim fat from a race car. It required submerging a metal component in an acid bath for a specified length of time to eat away a small amount of excess metal. However, if not strictly controlled, too much time in the acid vat could leave some components dangerously weak – hence the SCCA ban.

Although it is not clear how much – if any – “chemical milling” the ’69 Boss 302 racers were subjected to, it was an incredibly effective weight loss process that could remove more than one hundred kilos of excess weight. This tempted some teams to dip all components, including engine blocks and entire bodyshells! Acid dipping or not, the weight loss program for the Boss 302 racers was very effective, which included significantly thinner window glass and bolt-on panels (bonnets, boot lids, door skins, guards etc) stamped from thin gauge sheet metal.

However, weight loss was only part of the Kar Kraft process. Lessons learned from running stock-bodied sedans at 200mph on the NASCAR super speedways and Kar Kraft’s own GT 40 Le Mans program had exposed the considerable performance gains to be made from cars with good air penetration.

This was prevalent in sedans with inherently wedge-shaped silhouettes like the ’69 Mustang fastback. However, Kar Kraft took that a step further by trimming 25mm from the height of the radiator support panel; the engine bay inner guards were then tapered down from the firewall on each side to match. This substantially lowered the front aerodynamic profile of a Boss 302 race car. The inner halves of the rear wheel housings were also discreetly moved in-board by as much as 75mm on each side to provide adequate clearance for the 12-inch wide rear racing tyres, as only minimal flaring of the external wheel arch lips was permitted.

To maximise torsional rigidity, the shell was fully seam-welded and two sturdy braces were connected to the front suspension towers; one spanned directly across the engine bay between the two towers (which Moffat didn’t use) and another braced the towers rigidly to the firewall. The base of the towers were also treated to some substantial reinforcing plates as fitted to the road going Boss 302.

Inside the cabin was a fully welded tubular steel roll cage, which blessed the Trans-Am Mustangs with the strength of armoured tanks. Although the Kar Kraft cage designs of the Shelby and Moore teams differed in detail, they were fundamentally similar in that they extended beyond the cabin front and rear to integrate each suspension mounting point into the overall cage structure. This lack of chassis flex would ensured accurate and consistent suspension tuning and performance.

SUSPENSION

Kar Kraft engineers also went to town on the Boss 302 underpinnings, designing and manufacturing a suspension system based on the road car that was not only immensely strong but also blessed Ford’s ’69 Trans-Am warrior with the finest traction and handling in the business.

The front suspension subframe was notched about 20mm on either side where it bolted to the chassis, which had the effect of raising the sub-frame further into the car and permitting a lower static front ride height. This left only 25mm of belly clearance above the road surface and was another important gain in lowering the centre of gravity for optimum handling and cornering power. It also explains why (in combination with the tapered front sheetmetal) a standard 1969 Mustang looks so high at the front compared to Moffat’s Trans-Am version!

Front suspension was based on the architecture of the road car, but was considerably beefed up for Trans-Am duty. Forged steel stub axles on thick cast uprights were mounted between strengthened upper and lower swinging arms, with revised pick-up points for geometry best suited to the lowered ride height and camber change characteristics of wide racing rubber. Adjustable rose joints and solid metal bushings featured throughout, with competition coil springs, adjustable Koni shocks and adjustable anti-roll bar and a quick-ratio 16:1 steering box.

Rear suspension rules required that the road car’s live axle/leaf spring arrangement also be retained. As a result, Kar Kraft’s superb “full floater” nine-inch rear axle assembly (ie a full floater design ensured a broken axle would not result in a wheel parting company at speed) was located by race-tuned leaf springs and a pair of traction bars sitting directly above the springs and parallel to the road. These not only eliminated spring wind-up/axle tramp under hard acceleration, but also served as rigid trailing arms for positive fore and aft axle location.

Lateral control of the rear axle assembly was provided by Kar Kraft’s beautifully fabricated panhard rod. Like the front end, the rear suspension was equipped with adjustable Koni shocks and an anti-roll bar. The static rear suspension ride height of around 90mm which, when matched to the 25mm front ride height, explains why Kar Kraft’s Boss 302 Trans-Am race cars looked like they were literally being pulled down onto the track surface by magnetic force!

The net result was a superbly balanced and responsive chassis that blessed the Boss 302 Trans-Am racer with astonishing levels of traction, cornering grip and braking power which belied its modest engine capacity.

This was confirmed during a special track test conducted by the US Road and Track magazine at the time. One of the factory cars driven by George Follmer covered the standing quarter mile in a scant 12.9 seconds, generated just over one g of cornering force and almost halved the Boss 302 road car’s 130km/h braking distance from 90 metres to just 54!

“Most impressive,” commented the magazine staffers at the conclusion of the test. “It is our nature, maybe even our profession, to second guess and point out ways various people and companies could improve their products. For once, nothing. We don’t know how one would build a better Trans-Am car.”

Amen to that.

BRAKES

Manufacturers competing in the Trans-Am were allowed to upgrade the braking system for racing, provided the components were sourced from the parent company or its divisions. Kar Kraft engineers found what they needed for front brakes in Ford’s Lincoln luxury car division, by adapting huge 11.96-inch diameter ventilated rotors and four-spot Kelsey-Hayes callipers designed to stop multi-tonne land yachts like Lincoln’s obese Continental. These big stoppers were fed healthy doses of cooling air from large intakes mounted behind the grille. The road car’s rear drums were also removed and upgraded with the standard road car’s 11.3-inch front disc brake hardware. External adjustment of front to rear brake bias was also possible via a proportioning unit mounted under the floor adjacent to the rear axle.

The combination of Lincoln front brakes and Ford rears resulted in different wheel stud patterns front and rear, but under Australian racing rules all four wheels had to be interchangeable. Moffat had to re-drill his wheel centres so that they could be bolted to either end.

WHEELS/TYRES

Trans-Am rules specified a maximum wheel width of only eight inches. The Boss 302 racers rolled on a set of super lightweight magnesium wheels, either the American Racing rims or later the UK-built Minilites. Tyres were fat treaded racing rubber – 5.00 x 11.30 front and 6.00 x 12.30 rear.

ENGINE

The heart and soul of any Boss 302 Mustang – be it road or race car – is the big breathing, high revving 5.0 litre small block V8 engine under the bonnet. This was an engine specifically designed with one thing in mind and even today ranks as arguably the toughest small block pushrod production V8 ever to come out of Detroit.

The Boss 302 evolved as a result of the spectacular failure of the Tunnel Port 302 in 1968, not only with race reliability but also the fact that Ford never got around to proving to the SCCA that it had indeed produced the minimum 1000 of those exotic units needed to qualify for Trans-Am competition! Like all manufacturers competing in the series, Ford’s Engine and Foundry division engineers were faced with the challenge of cost effectively producing a race engine on a mass production assembly line. Clever use of existing “regular production” engine components would be needed to meet such a requirement.

After plenty of mixing and matching, it was discovered that the big breathing cylinder heads from the all-new “Cleveland” 351ci (5.8 litre) small block V8 (named after the city in Ohio where the new engine was produced) featured the same bolt pattern and bore spacing as the four-bolt main “Windsor” cylinder block used as the basis of the Tunnel Port 302. The new mass-produced cast iron Cleveland heads were well suited to high performance applications and in many ways were superior to the Tunnel Port heads.

The Cleveland items featured a canted valve design (ie inlet and exhaust valves inclined towards the combustion chamber from opposite directions) which ensured unimpeded gas flow due to an excellent configuration of the inlet/exhaust porting. The huge 2.23-inch intake and 1.71-inch exhaust valves (which were in fact slightly larger than the exotic Tunnel Port) and semi-hemispherical combustion chambers were further evidence of the new Cleveland’s big lung capacity and competition breeding. Although some of the water jacket passages would need to be slightly modified to suit, the marriage of 351 Cleveland heads with 302 Windsor block became the basis of Ford’s new Trans-Am killer.

However, before this new combo could be approved, in late 1968 it was vigorously track tested against two other engines still under consideration by Ford for use in the 1969 Trans-Am series – the unloved Tunnel Port 302 and the more exotic Gurney- Westlake-headed 302. Although the Gurney-Westlake version, with its all-alloy casting and integral inlet manifold) proved the fastest of the three, followed by the Boss and the Tunnel Port, the Boss version was given the nod due largely to its use of existing production componentry and the subsequent ease of producing it numbers to satisfy Trans-Am requirements.

The Boss 302 engine was produced in both road and full race specifications. 110 special race versions were cast, featuring four-bolt bottom ends, “dry-deck” head sealing (ie crushable o-rings that seated in grooves at the top of each cylinder bore as opposed to conventional head gaskets) and a different oiling system design to suit the new Cleveland heads. These were equipped with lightweight valve sets, super strong valve springs, screw-in rocker studs, steel guide plates for the solid lifter camshaft pushrods, 1.73:1 aluminium roller rockers and improved top end oiling.

Considering the sustained high rpm required to get the best out of the new engine in racing conditions, Ford engineers equipped the new Boss 302 with an induction system that could more than satisfy its thirst. Sitting up top was not one but two gigantic 1050cfm (or 1235cfm) sancast Holley Dominator four-barrel carburettors (They were quite expensive to make!) mounted in line on an independant runner alloy inlet manifold. A special off-set distributor was also required to clear the front carby. These giant fuel jugs were fed cool, dense air via a fully enclosed airbox connected to twin inlet pipes mounted behind the grille. By comparison, the road version came with a single 780cfm Holley.

A variety of induction systems were trialled during the Boss race engine’s development. This included a quartet of twin-choke downdraught 48mm IDA Weber carburettors which proved so successful on Moffat’s car in Australia (Moffat’s carbs were enlarged to 51mm chokes).

Also developed was a high rise-style alloy inlet casting called the “Cross-Boss” that mirrored that of GM’s “Cross-Ram Trans-Am” unit used by Camaro racers. Ford’s Cross-Boss featured two giant Holley four-barrels mounted in an offset arrangement (ie one at the right front, one at the left rear) of the engine but was less effective than the in-line design.

Below decks was a forged steel, cross-drilled crankshaft with anti-frothing windage tray, high volume oil pump with triple pick-ups and a big capacity baffled sump to combat oil surge. Thick connecting rods with much meatier big end supports were coupled to 12:1 forged alloy pistons (road versions used 10.5:1 compression ratio).

Large diameter, equal length tubular steel exhaust headers dumped the spent gases through huge, unmuffled side pipes. A large capacity aluminium coolant radiator and oil cooler kept the lid on engine temps.

In 1969, Ford teams claimed a fully race-prepared Boss 302 engine was producing over 470bhp (350kW) by mid season and could endure up to a staggering 8000rpm in the heat of battle. Mustang racers often complained that the Boss 302 had inherited some of the Tunnel Port’s lack of low and mid-range torque because of its enormous breathing capacity, but no one ever complained about its formidable top-end punch!

Not surprisingly, Ford’s official power ratings for the factory rev-limited Boss 302 road car were capped at a modest 290bhp (216kW) @ 5800rpm. While many accept that these quoted power figures were primarily aimed at keeping the insurance companies happy, those in the know claim the street Boss was good for as much as 350bhp (260kW) – especially with the 6150rpm factory rev limiter disconnected!

TRANSMISSION/DRIVE-TRAIN

Two versions of the Ford Top Loader four speed gearbox were available on the Boss 302 road car. A wide-ratio version (2.78 1st gear) was standard issue and a close-ratio (2.32 1st gear) unit was optional. Top Loaders with a variety of ratios were available for the race cars.

1969 Boss Mustangs came equipped with a nodular iron cased nine-inch differential assembly and indestructible 31-spline axle shafts. Standard rear axle ratio was 3.50:1 with optional 3.91 and super short 4.30 gear sets. A remote oil cooler and Traction-Lok limited-slip centre were also available as options. The race cars were fitted with a pair of differential oil coolers, which were located under the car just in front of the rear axle and relied on underbody air flow for cooling.

COCKPIT

The driver’s compartment of a Boss 302 racer was bare and business-like. For Trans-Am duty, all the standard carpet, seating and interior trim were removed bar the dashboard pad, which was retained with a new purpose-built instrument panel directly in front of the driver. Other driver aids included a deeply dished sports steering wheel, a hip-hugging competition bucket seat which sat the driver virtually on the floor, a padded head rest attached to the roll cage and a full multi-point seatbelt harness. This could be tightened very firmly by a special ratchet-style tensioner system used in Airforce fighter jets, which was operated by a small crank handle located next to the driver on the transmission tunnel. There was also an auxilliary switch box for the car’s main control systems mounted on the tunnel and an on-board fire extinguisher system. The rear edge of the driver’s door was secured internally by additional bonnet pin-style clips top and bottom, to ensure the door would not spring open due to impact damage in the heat of battle. This was a cockpit built for serious combat.

Allan Moffat regarding the modifications made to his beloved Mussy in a class that was VERY liberal to say the least: “From memory we also might have put some of the original panels in storage and replaced them with fiberglass ones and experimented with a dry sump system, but we did nothing to hurt the integrity of the car. That’s why David Bowden has such a precious original example of 1970s Australian motor sport history today. ”

DAVID BOWDEN: RESTORING A LEGEND

AMC has featured several examples from David Bowden’s definitive stable of famous Australian competition muscle cars, but he readily admits that Allan Moffat’s Mustang is the “cornerstone” of his priceless collection. For many years, Bowden could only dream of owning such a car, until an offer to buy it from none other than the man himself.

“We were at Bathurst for the ATCC round in 1995, ” Bowden recalls. “We had just completed the restoration of Pete Geoghegan’s Super Falcon and taken it there for Pete to drive around in front of the field on the parade lap. Anyway, Allan (who was providing TV commentary) turned up to have a look at the car in the pits. You can imagine how the crowds started to swirl around with Moffat, Geoghegan and the Super Falcon together in the one spot!

“Allan had a close look over the restoration and his eyes went about a foot wide. He said to me ‘this is what the Trans-Am needs, you come down to Melbourne next week and we’ll do a deal. I want you to buy the Trans-Am.’ The car was in storage at Holman-Moody in the US at the time, so I flew down to Melbourne during the week and bought the car without even seeing it. It was a once in a lifetime opportunity.”

The Mustang had been in the US for some time but had not found the “right” buyer. The car was loaded with spare parts and safely packaged up by Lee Holman before it was shipped back to Australia, arriving at the Brisbane docks two months later. Moffat also sent a whole heap of parts like spare cylinder blocks, the inlet manifold for the quad-Weber carbs, etc to assist Bowden with the restoration.

“When we got the car back from the States it was fitted with a Bud Moore manifold and single Holley four-barrel which they had to run in the 1970 Trans-Am series,” Bowden says. “That was how Allan was trying to sell it in the US, because Americans just couldn’t relate to a Trans-Am Mustang with four Webers on it.”

The body restoration burned up around six months at Omega Auto Bodyworks at Caloundra. In addition to getting the steel panels gun-barrel straight and applying a new skin of Coca-Cola red war paint, Bowden insisted that the substantial wheel arch flares (fitted to the car when competing as a Sports Sedan in Brut 33 colours) be replaced with the smaller, more handsome flares seen during its “Improved Production” days. The end result is superbly authentic.

The Boss 302 engine also needed a full rebuild, following a post-restoration test drive at Lakeside that revealed a bent connecting rod. Bowden says Moffat generously supplied a brand new set of factory con-rods he had “under his bed” and the engine was first rebuilt at Jeff Barnes Performance and just recently (2011) rebuilt again in house by the Bowden’s team of mechanics.

The Moffat Mustang is the cornerstone of our muscle car collection,” Bowden claims. “It’s just the best muscle car Australia has ever had. This car just has to stay in Australia. Mate, even if I was going broke I still would not sell that car overseas. I could never live with myself. I also made a promise to Allan when I bought the car that apart from me, he would be the only person allowed to drive it and I have stuck to that promise. On many occasions my good mate, the late Pete Geoghegan, said he would really like to drive it, just to get a taste of what he’d been up against during those great battles of the past, but I had to refuse even his request.

“There’s just something very special about it. I still get a tingle every time I open the garage door and when I drive it (during display laps at Historic race meetings) I feel like an impostor. You know, everyone’s waving madly at you and it makes you feel like you’re Allan Moffat, but of course you know you’re not. I shudder to think how hard Allan must have driven it.

“My greatest memory of seeing the Mustang in action was the ATCC final at Oran Park in 1971. It was super-human the way Moffat drove the car that day. Bob Jane in the 427 Camaro was so lucky to win. That was just some of the best race driving I have ever seen. Moffat was at his best in this car when he was wild. The wilder he got, the better he drove it and that’s why he and Jane used to have such incredible battles.”

SPECIFICATION

No of Cylinders: 8

Cubic Capacity: 5000

Horsepower: 485

Aspiration: Quad 48 IDA Webers

Transmission Type: Borg Warner T-10, or Ford Toploader